SPECIAL

CUT COSTS

AND INCREASE EFFICIENCY:

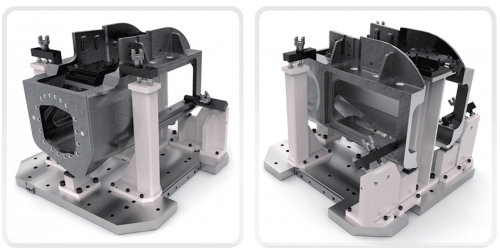

[ design and production of turnkey solutions and equipment

[ automation with manual, hydraulic or pneumatic fi xing

[ production and customisation

[ continual collaboration with your technicians for the best result

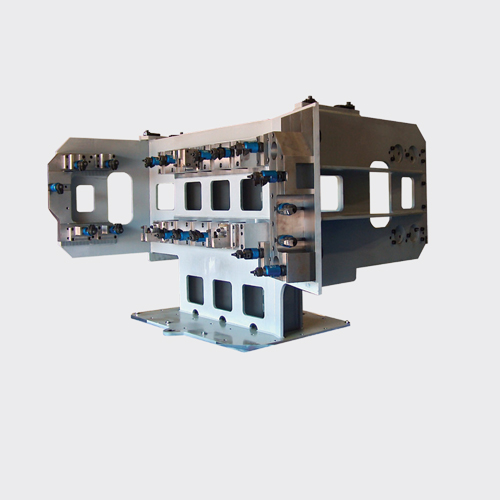

[ clamping systems, vices, clamping elements for robots and material handling systems

[ workholding systems, vices, clamping bars, locators, automations

[ supports, dovetails, support blades, blade guides, spacers, flanges

[ more than thirty years of experience with special equipment

[ cuts your costs

[ increases your production

[ improves your flexibility

[ aims at efficiency and precision

PROJECTS

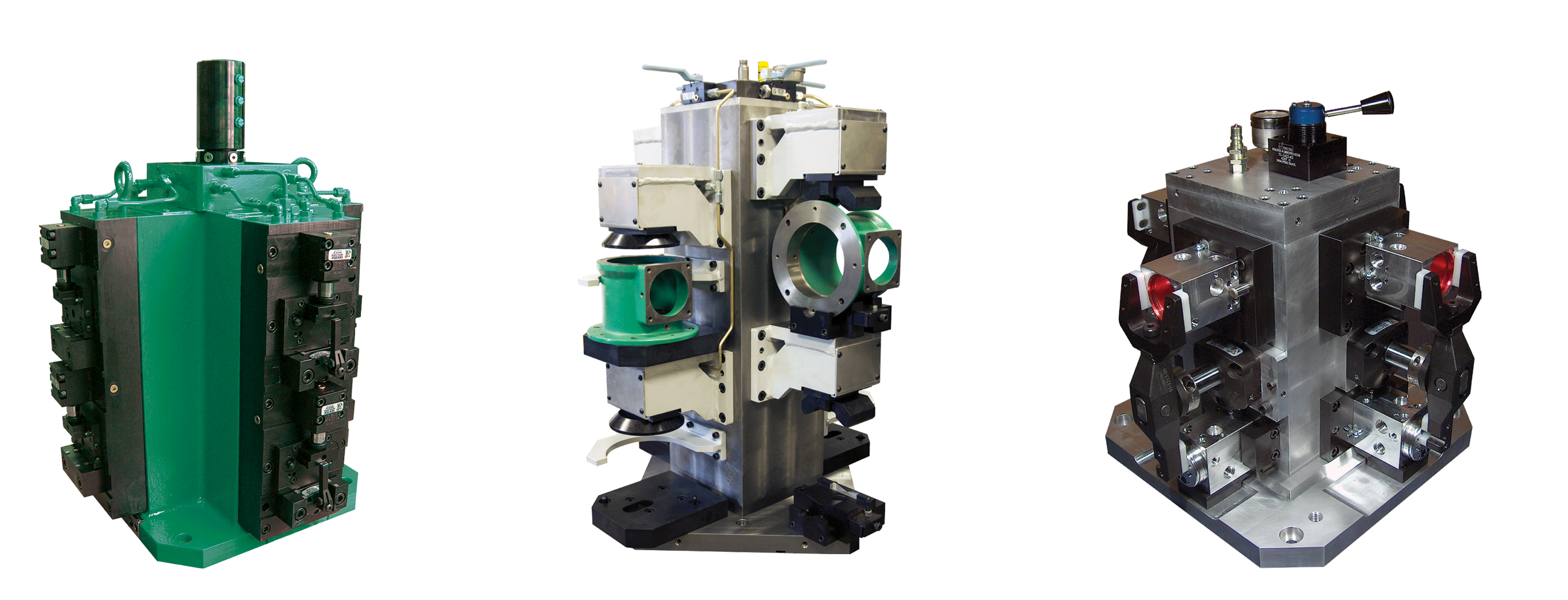

FOR EVERY MACHINE TYPE

[ HORIZONTAL CNC MACHINING CENTRES

[ VERTICAL CNC MACHINING CENTRES

[ CNC MILLING MACHINES

[ CNC LATHES

[ MULTI-AXIS MACHINES

[ CNC GRINDING MACHINES

[ SAWS AND LOTS MORE

PROCESS

CONTROL

All our equipment is designed, built, assembled and tested in our factory

PRECISION

AND SAFETY

Each component is checked using sophisticated measuring systems to give you the precision you need. measurement reports and other certifications are available on request

COLLABORATION AND DIRECT DIALOGUE

You can always talk directly with our designers to develop and refine the most suitable solutions for your work together.

Our design service can also supply you with a 3d model (solidworks) of the component, so you can verify everything in the best way possible. Our mission is to be your tooling department.

CUSTOM FIXTURES

AND WORKHOLDING SOLUTIONS:

[ CLOSING AND OPENING OF ALL CLAMPS SIMULTANEOUSLY

[ HIGH CLAMP TIGHTENING POWER

[ PRECISE, REPEATED POSITIONING

[ ELIMINATION OF POSSIBLE OPERATOR ERRORS AND INCREASED SAFETY

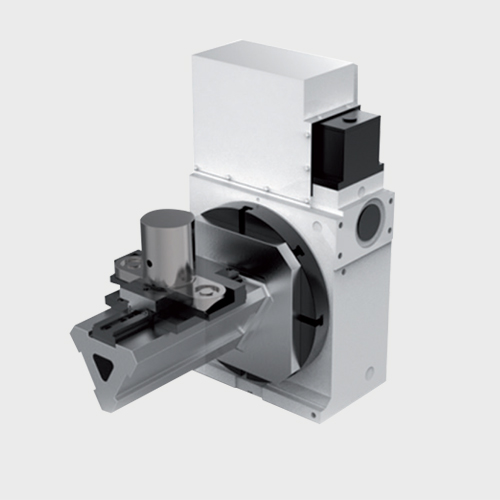

SPECIAL CLAMPS

DECREASE FIXING TIMES DRASTICALLY

INCREASE SAFETY AND SPEED

ADAPT PERFECTLY TO YOUR WORK AND YOUR COMPONENTS

GRIPPING SYSTEM

Don’t know how to lock your piece?

Looking for a clamp system that reduces handling to a minimum?

SUPPORTS

SUPPORT BLADES

BLADE GUIDES

WORK GUIDES